We Are At The Forefront…

Of Trenchless Technology. Through Horizontal Directional Drilling, We Provide Safe, Cost Effective Installations In Four Key Areas:

Telecom

Electric & Power

Gas

Water & Sewer

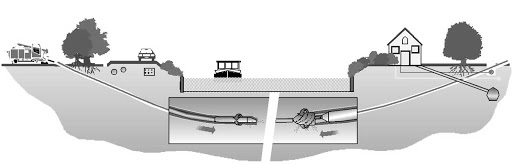

Horizontal Directional Drilling (HDD), has become a viable and cost-efficient method for installing underground utilities and conduits for both homeowners and businesses alike. HDD is very attractive because it allows water lines, sewers lines, power lines, fiber optic conduits, traditional cable conduits, irrigation lines, gas lines, and telephone lines to be installed with minimal or no disruption to landscaping, driveways, sidewalks.

Directional drilling allows operators to drill (bore) horizontally without having to create an open trench or disturb the surface conditions across an expanse of ground. Traditionally, equipment or manpower would be required to dig up the ground to create a trench to place pipe or conduit in and then backfill, destroying the existing landscape. The process would take days or weeks and was, on the overall, highly obtrusive, and destructive. Directional drilling changes that.

Directional drilling allows operators to drill (bore) horizontally without having to create an open trench or disturb the surface conditions across an expanse of ground. Traditionally, equipment or manpower would be required to dig up the ground to create a trench to place pipe or conduit in and then backfill, destroying the existing landscape. The process would take days or weeks and was, on the overall, highly obtrusive, and destructive. Directional drilling changes that.

Directional drilling requires the use of a drilling machine that is usually no larger than 2m wide and 4 meters long and 2 workers. One worker operates the drill while the other worker uses an electro-magnetic device called a locator. The locator tracks the tip of the drill and can tell the operator exactly where the drill head is horizontally, at precisely what depth it is, what amount of pressure it is exerting. While it is boring a hole horizontally, a clay compound called bentonite is often injected in as a mud to help maintain ground stability.

Once the drill head reaches the desired location, conduit is then connected to the drill head and the conduits are pulled back in the same horizontal hole that was bored. There are only 2 holes created to complete a directional drill shot, one at the entry spot for the drill to enter the ground, called a “push pit” and a second at the final location or destination of the conduit, called a “pull pit.”